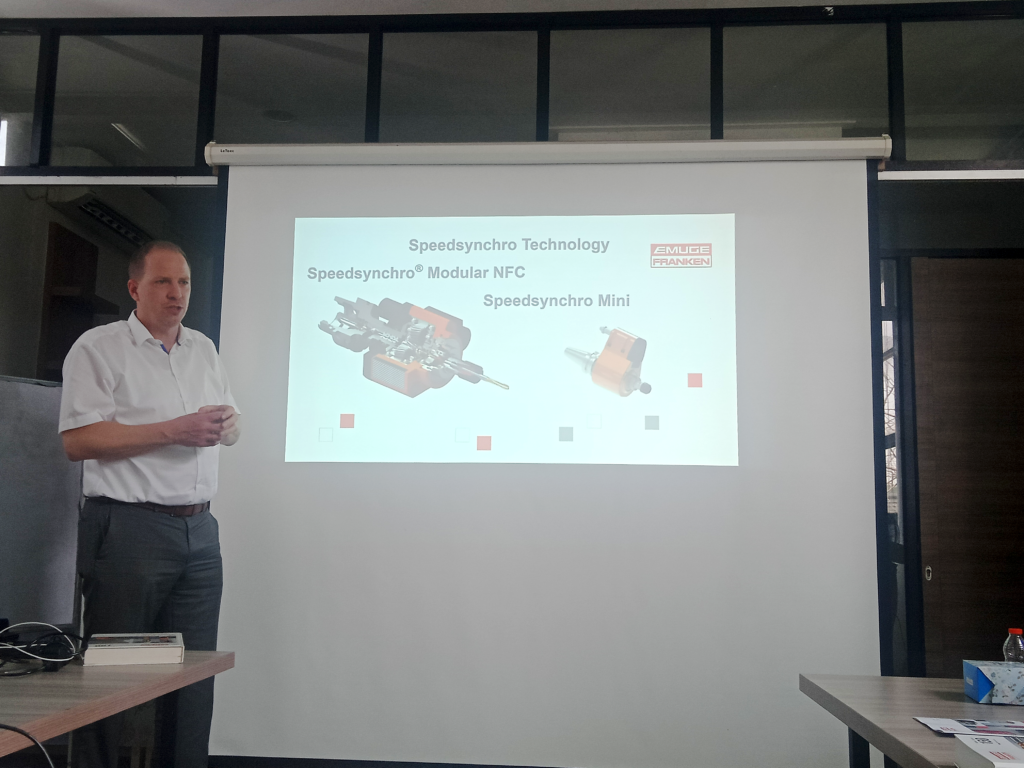

Hari/tanggal: SENIN,13 MARET 2023

Waktu: 10:00 WIB s/d 15:00 WIB

Tempat : Kantor PT. EMUGE FRANKEN INDONESIA

PT. LASTIKA PRIMA TEKNIK – pada hari senin tanggal 13 maret 2023 TEAM sales PT. LASTIKA PRIMA TEKNIK sedang mengikuti training EMUGE – FRANKEN. tujuan kami mengikuti training EMUGE – FRENKEN mempelajari dan mengenal produk dari EMUGE – FRANKEN. EMUGE-FRANKEN telah menjadi salah satu produsen perkakas terkemuka di dunia untuk threading, pengeboran, milling, pengujian, dan clamping selama lebih dari 100 tahun. EMUGE – FRANKEN adalah penyedia sistem untuk alat pemotong dalam desain standar atau alat khusus yang disesuaikan untuk proses pembuatan yang berbeda. Alat threading, pengeboran, dan milling EMUGE-FRANKEN memungkinkan pemesinan yang sangat efisien dalam produksi seri dan menampilkan masa pakai alat yang mengesankan, bahkan saat mengerjakan material yang menantang. Kisaran alat pemotong, dilengkapi dengan alat untuk menjepit benda kerja dan alat, memenuhi tuntutan kualitas dan presisi tertinggi. Untuk hasil pemesinan yang optimal, EMUGE – FRANKEN menyediakan alat dalam versi karbida padat (VHM) dan baja kecepatan tinggi (HSS). Penajaman ulang dan pelapisan ulang masing-masing merupakan komponen penting untuk penggunaan ekonomis. salah satunya seperti

Thread Technology – Machine tap

- New carbide taps for compacted graphite iron

The highly abrasive cast iron materials with vermicular graphite have special microstructures that require specific tool properties. In addition to the special CGI geometry with an extremely robust cutting edge design, the TICN coating of the new carbide versions has been adapted and optimised to enable long tool life.

Under suitable machining conditions such as high stability of the component, use of a synchronous spindle or a Softsynchro tool holder with minimum length compensation, tool life increases of at least 3 times can be achieved with the carbide version compared to HSSE-PM tools.

The carbide taps, which are available with chamfer forms C and E for use with a thread depth of up to 2xD, have an axial internal cooling lubricant supply. The taps can be used universally in through-holes and blind holes if they are used with a cooling disc on the tool holder. The new CGI carbide taps are available in solid carbide design in the dimensions M4-6HX to M10-6HX. The tools feature a solid carbide head for the dimensions M12-6HX to M20x1.5-6HX as well as MF12x1.5-6HX to MF20x1.5-6HX.

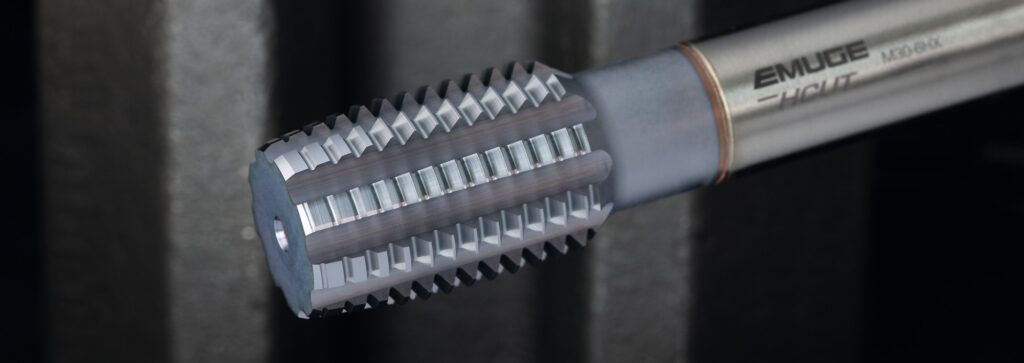

- More dimensions for high-strength steels

EMUGE´s HCut tool geometry is the suitable tool programme for thread cutting in high-strength or hardened steels, which enables process-reliable thread production with specially adapted flute shape and suitable rake angles and clearance angles. EMUGE offers the HCut taps in the cutting materials HSSE-PM and carbide in order to optimally machine different hardness properties of materials. EMUGE recommends using the HSSE-PM tap version for material hardness of 44 to 55 HRC, as is the case with the SSAB steels Toolox 44 or Armox 500T. The carbide version is designed for use at hardness of 55 to 63 HRC, which can be found, for example, in the SSAB steels Strenx 1300, Hardox 500, 600 or Extreme.

The taps with a solid carbide head are now available in the diameters M20, M24 and M30 in the tolerance 6HX. They feature a chamfer form C or D, the latter being recommended for through-holes. Besides their special geometry, the tools also have an optimised TICN coating to ensure high process reliability.

Drilling technology

EF-Drill – the solid carbide twist drill programme from EMUGE – is the result of extensive development work in which the latest know-how regarding tool geometry, cutting material and coating have been incorporated. The drill specifications guarantee excellent hole quality, and the twist drills have also been perfectly adapted for predrilling tap holes for threading tools.

The twist drills are available with four geometries STEEL, VA, GG and HCUT which cover a wide range of applications for almost all workpiece materials.

- STEEL for ISO material groups P, M, K, N

- VA for M, N und S

- GG for K

- HCUT for H

The EMUGE twist drill programme comprises five product lines:

EMUGE Basic-Drill

- Universally applicable with a focus on steel materials

- Smooth chip evacuation and optimised guidance

- High-performance coating for higher cutting speed and feed values

- Diameter range 3.0 to 16.00 mm

EF-Drill Micro

- Especially for very small drill holes

- Available in STEEL-Geometry

- Dimension range from 0.75 to 3.00 mm

EF-Drill

- Available with geometries STEEL, VA, GG and HCUT

- Dimension range from 2.80 to 20.00 mm

EF-Drill Modular

- With exchangeable cutting head

- Available in STEEL-Geometry

- Dimension range from 14.00 to 32.00 mm

EF-Drill C

- Chamfer drill 90º

- Available with geometries STEEL and VA

- Dimension range from 2.80 to 15.50 mm

- Variable step length in mm increments

EMUGE PunchDrill

- Double feed with the same axial force

- Machining of cast aluminium alloys with at least 7% Si content

- Drilling depth up to approx. 8 x D, nominal diameter range from 3.3 mm to 12 mm

- Excellent centring capability results in high positioning accuracy of the holes

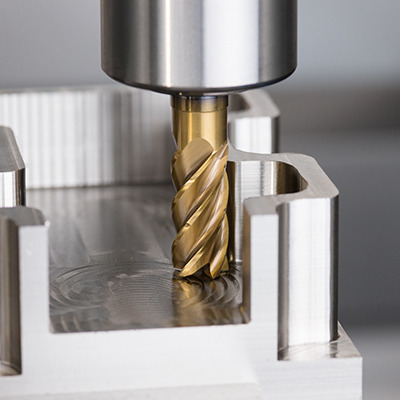

Milling technology

The FRANKEN brand is characterised by a diversity of milling tools. Precision and innovation characterise the wide range of carbide and HSS milling cutters as well as PCD, CBN or indexable end mills. The production in our German manufacturing plant in Rückersdorf ranges from standard end mills and bore cutters through ball nose and torus end mills to high-precision special form and profile milling tools.

Our product lines support orientation and structure the product range material-related:

- FRANKEN TiNox-Cut for machining titanium, nickel-based alloys and stainless steels

- FRANKEN Alu-Cut for machining aluminium alloys

- FRANKEN Hard-Cut for machining hard materials up to 66 HRC

- FRANKEN Top-Cut for many materials and universal use

machining-related:

- FRANKEN Multi-Cut for high-performance roughing

- FRANKEN Jet-Cut for HPC-, HSC- or trochoidal machining

FRANKEN Micro for micro machining

ndustry-related:

FRANKEN Turbine for aerospace and turbine industry

FRANKEN Dental for dental laboratories

according to technical characteristics:

- FRANKEN Expert with specific product features for mould making, turbine blades, additive manufacturing and polished surfaces

Dan bahkan masih banyak lagi produk dari EMUGE – FRANKEN

Distributor Cutting Tools di Indonesia

PT. LASTIKA PRIMA TEKNIK adalah distributor resmi cutting tools di Indonesia.

Jika Anda ingin berdiskusi seputar cutting tools untuk mendukung bisnis Anda, silahkan hubungi kami melalui nomor yang sudah tertera

Kunjungi juga halaman instagram, dan linkedin kami untuk mendapatkan update terbaru seputar peralatan industri lainnya.